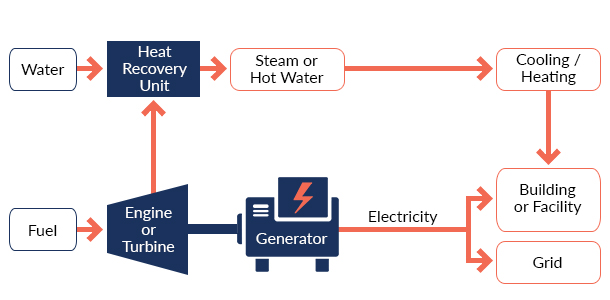

Combined heat and power (CHP) is a highly efficient, combined process which integrates the production of usable heat and power.

Conventionally, as electricity is generated, there is a huge amount of heat lost. The efficiency of the process is therefore reduced as the heat could be used in other ways. You can physically see the heat being wasted as the steam coming out of a power plant’s cooling towers. In coal and gas fired power stations, two thirds of energy is lost this way

Generating electricity in a conventional power station has four main stages. First, fuel is burnt which boils water to create steam, in turn forcing a turbine to spin. The turbine turns the generator, producing the electricity which then goes to the transformers in order to produce the correct voltage. It’s the water that’s boiled into steam, to drive the turbines, that causes the inefficiency issue; cooling it back down in the giant cooling towers wastes huge amounts of energy.

In the CHP process, heat normally wasted in electricity generation is captured and supplied to local buildings. A CHP plant makes both electricity and hot water, and instead of allowing the latter to escape in steam, it supplies both products to customers. Due to the fact it supplies hot water, the level of efficiency a CHP plant can achieve depends on its proximity to the building it serves, meaning smaller power plants located near communities work best.

CHP has a high efficiency rating of over 80%. Compared to this, coal-fired plants have the lowest range of efficiency at 35%-38% despite them producing 41% of the world’s electricity generation.

Another positive of CHP is that it’s fuel neutral; it can be applied to both renewable and fossil fuels which makes more efficient use of primary energy resources (a source of energy that occurs naturally). Many industrial, large commercial or institutional applications procure energy using CHP; major benefits of using combined heat and power are that it has few location restrictions and provides a relatively low investment cost. Perhaps best of all, CHP takes the pressure off power stations; reducing the national energy requirements by providing an alternate source.

There are five common CHP technologies. These are: fuel cells, gas turbines, micro turbines, steam turbines and reciprocating engines. Fuel cells convert the chemical energy in the fuel into electricity through an electrochemical process. A gas turbine produces an electric current at the heart of the power plant; it can convert natural gas or other liquid fuels into a mechanical energy. Microturbines turn electrical generators by burning both liquid and gaseous fuels to create a high speed rotation. Steam turbines are common for CHP installations; extracting thermal energy from pressurised streams and use this to do mechanical work on a rotating output shaft. Reciprocating engines are well suited for CHP as they are often fuelled by natural gas.

If you want to learn how CHP could benefit your business, please don’t hesitate to contact The Energy Network for a more in depth discussion!